Concrete pipe seals, also known as concrete pipe gaskets or concrete pipe joints, are crucial components used in the construction of concrete pipelines. These seals are designed to provide a secure and watertight connection between concrete pipes, preventing the leakage of fluids or contaminants and ensuring the structural integrity of the pipeline. Here’s more information about concrete pipe seals:

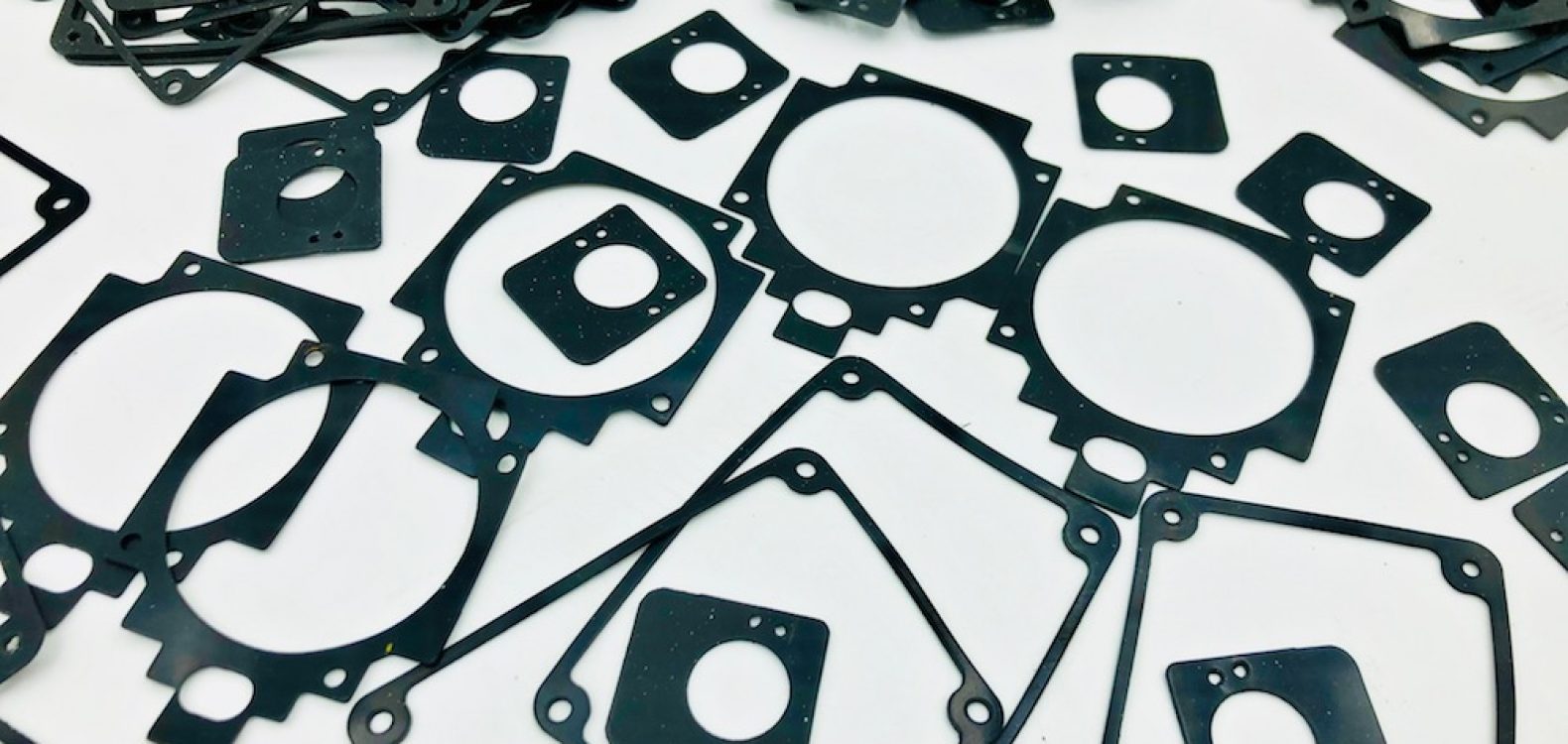

- Materials: Concrete pipe seals are typically made from durable elastomeric materials such as natural rubber, synthetic rubber (e.g., EPDM, neoprene), or thermoplastic materials. These materials offer flexibility and resilience, allowing the seals to maintain their integrity under pressure, temperature variations, and environmental exposure.

- Types:

- Rubber Ring Joint (RRJ): RRJ seals are the most common type used in concrete pipe connections. They consist of a rubber ring or gasket that is seated in a groove in the spigot end (male end) of one concrete pipe. When two pipes are joined, the gasket creates a watertight seal between them.

- Lubricated Joint: In lubricated joints, a lubricant is applied to the gasket to reduce friction and ease the assembly of the pipes. This can be particularly useful when dealing with large-diameter concrete pipes.

- Compression Gasket: Compression gaskets are used in conjunction with a concrete collar to create a seal. The collar is compressed around the gasket, ensuring a secure and tight connection.

- Functions:

- Watertight Seal: The primary function of concrete pipe seals is to provide a watertight seal between concrete pipes. This prevents the leakage of sewage, stormwater, or other fluids, ensuring that the pipeline operates efficiently and minimizes environmental impact.

- Structural Integrity: Seals also help maintain the structural integrity of the pipeline by preventing soil infiltration and erosion around the pipe joints.

- Resistance to Movement: Concrete pipe seals accommodate slight movements and settlement, helping to prevent joint displacement or damage.

- Applications: Concrete pipe seals are commonly used in various infrastructure projects, including:

- Sanitary Sewer Systems: They are used to connect sewage pipes in municipal wastewater systems.

- Stormwater Drainage: Concrete pipe seals are employed in stormwater management systems.

- Culverts and Drainage Channels: They are used in the construction of culverts and open drainage channels.

- Irrigation: In agricultural and landscaping irrigation systems.

- Installation: Installing concrete pipe seals requires proper alignment and careful handling of the pipes to avoid damaging the seals during assembly. The gaskets should be lubricated when necessary to facilitate jointing.

- Maintenance: Regular inspection and maintenance of concrete pipe seals are essential to ensure their continued effectiveness. Damaged or deteriorated seals should be promptly replaced to prevent leaks and maintain the pipeline’s performance.

In summary, concrete pipe seals are vital components in the construction and maintenance of concrete pipelines, providing watertight and secure connections. Their proper selection, installation, and maintenance are critical to the longevity and efficiency of infrastructure systems that rely on concrete pipes.