EPDM (Ethylene Propylene Diene Monomer) rubber seals are widely used for their excellent sealing properties, flexibility, and resistance to environmental factors such as weather, UV radiation, and a range of chemicals. These seals are commonly employed in various industries and applications where effective sealing is crucial. Here’s more information about EPDM rubber seals:

- Material Characteristics:

- Weather Resistance: EPDM rubber seals are highly resistant to outdoor weather conditions, including sunlight (UV rays), rain, snow, and extreme temperatures. This makes them suitable for both indoor and outdoor applications.

- Chemical Resistance: EPDM rubber exhibits good resistance to many chemicals, acids, and bases, making it suitable for applications where exposure to chemicals is a concern.

- Temperature Range: EPDM rubber has a broad operating temperature range and can withstand high and low temperatures without losing its sealing properties.

- Flexibility: EPDM rubber is flexible and can conform to irregular shapes and surfaces, making it effective for creating a secure seal.

- Applications:

- Automotive: EPDM rubber seals are commonly used in the automotive industry for door and window seals, weatherstripping, engine gaskets, and more.

- Construction: In construction, EPDM rubber seals are used for sealing windows, doors, roofing, and HVAC systems.

- Electrical: EPDM seals are employed in electrical enclosures and cabinets to provide environmental seals and protect against moisture and dust.

- Industrial: EPDM seals are used in various industrial applications, including sealing flanges, pipes, tanks, and equipment.

- Marine: Due to their resistance to saltwater and UV radiation, EPDM rubber seals are used in marine applications for hatch seals, porthole gaskets, and more.

- Agriculture: EPDM seals are used in agricultural equipment and machinery for sealing purposes.

- Food and Beverage: In the food industry, EPDM seals are used in processing equipment and containers, where FDA-compliant materials are required.

- Types of EPDM Seals:

- O-Rings: EPDM O-rings are used for dynamic sealing applications where compression and deformation are necessary to create an effective seal.

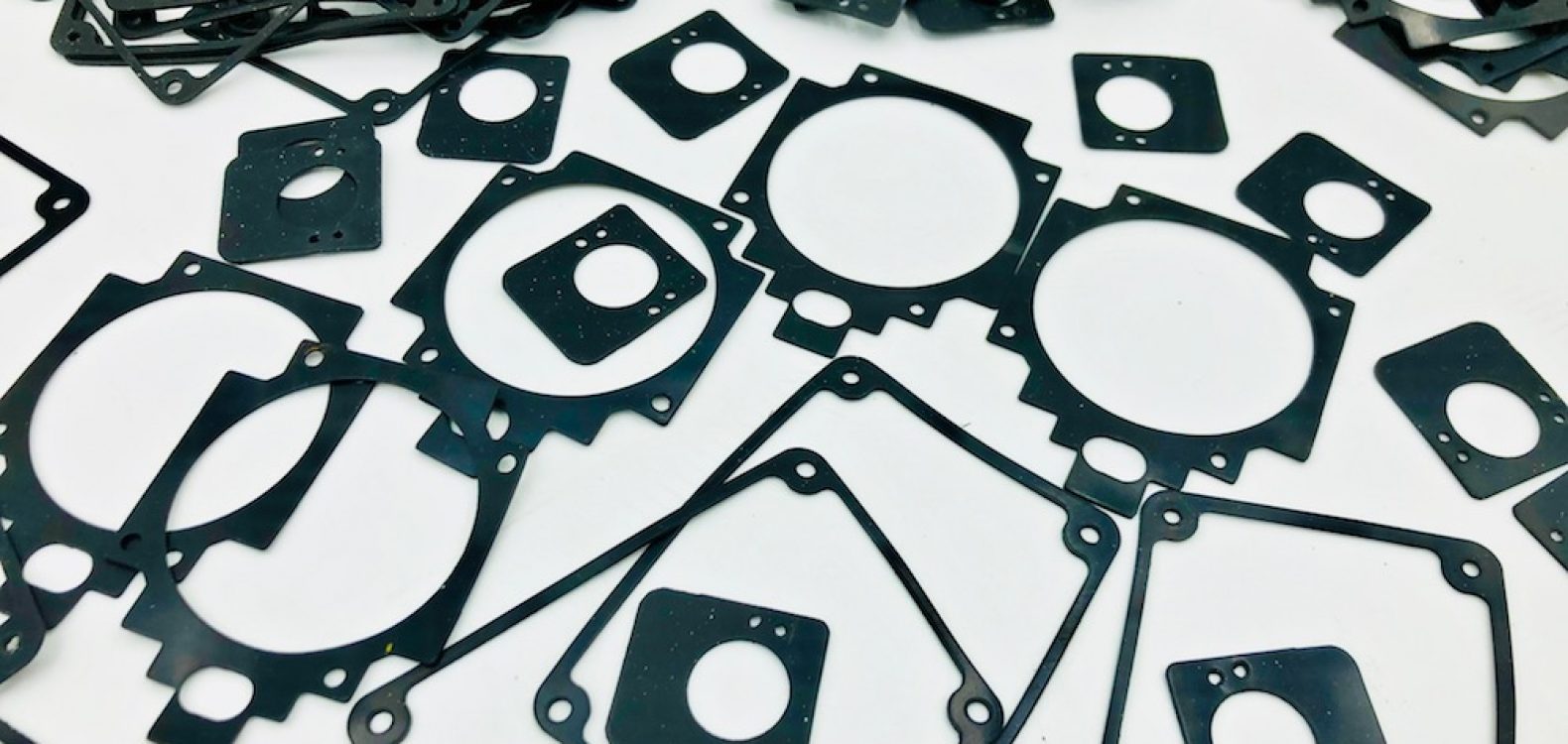

- Flat Seals: Flat EPDM rubber seals are used in static sealing applications where two surfaces come together with little to no movement.

- Gasket Strips and Sheets: EPDM rubber is also available in sheet or strip form, which can be custom-cut to fit specific applications.

- Installation and Maintenance:

- Proper installation, including selecting the right seal type and ensuring a clean and dry sealing surface, is crucial for effective sealing with EPDM seals.

- Regular inspection and maintenance are necessary to monitor the condition of EPDM seals. Over time, exposure to UV radiation and environmental factors can cause wear and deterioration, necessitating replacement.

- Compliance and Standards:

- Depending on the application, EPDM rubber seals may need to meet specific industry or regulatory standards, such as ASTM or FDA (for food-grade applications).

EPDM rubber seals offer versatility and reliability in a wide range of sealing applications. Their ability to maintain sealing integrity in demanding environments and resistance to weathering makes them a popular choice for many industries. Proper selection, installation, and maintenance are essential for ensuring their long-term performance.