A dilatation seal, often referred to as an expansion joint or expansion seal, is a specialized structural component designed to accommodate the expansion and contraction of materials or structures due to temperature variations, seismic activity, settling, or other dynamic forces. These seals play a crucial role in various industries and construction applications, including building infrastructure, transportation, pipelines, industrial facilities, and more. The following is a comprehensive description of dilatation seals, their functions, types, materials, and applications.

**1. ** Function:

Dilatation seals primarily serve two fundamental functions:

a. Expansion: These seals allow materials or structures to expand in response to elevated temperatures, preventing excessive stress or damage. When materials heat up, they expand, and without expansion joints, this thermal expansion could cause buckling, warping, or cracking.

b. Contraction: Conversely, when temperatures drop, materials contract. Dilatation seals accommodate this contraction, preventing gaps, leaks, or structural failure.

2. Types of Dilatation Seals:

Dilatation seals come in various forms, each tailored to specific applications. Common types include:

a. Expansion Joints: These are flexible connectors that absorb thermal expansion and contraction in structures. They can be found in buildings, bridges, and roadways.

b. Pipe Expansion Joints: Used in piping systems, these seals absorb movement in pipelines due to temperature fluctuations and vibrations.

c. Control Joints: Typically used in concrete and masonry structures, control joints control cracking by allowing for controlled movement.

d. Isolation Joints: These prevent the transfer of loads, vibrations, or deformations from one part of a structure to another.

e. Compression Seals: These seals provide a watertight or airtight connection, often used in high-pressure applications, such as tunnels or dams.

3. Materials:

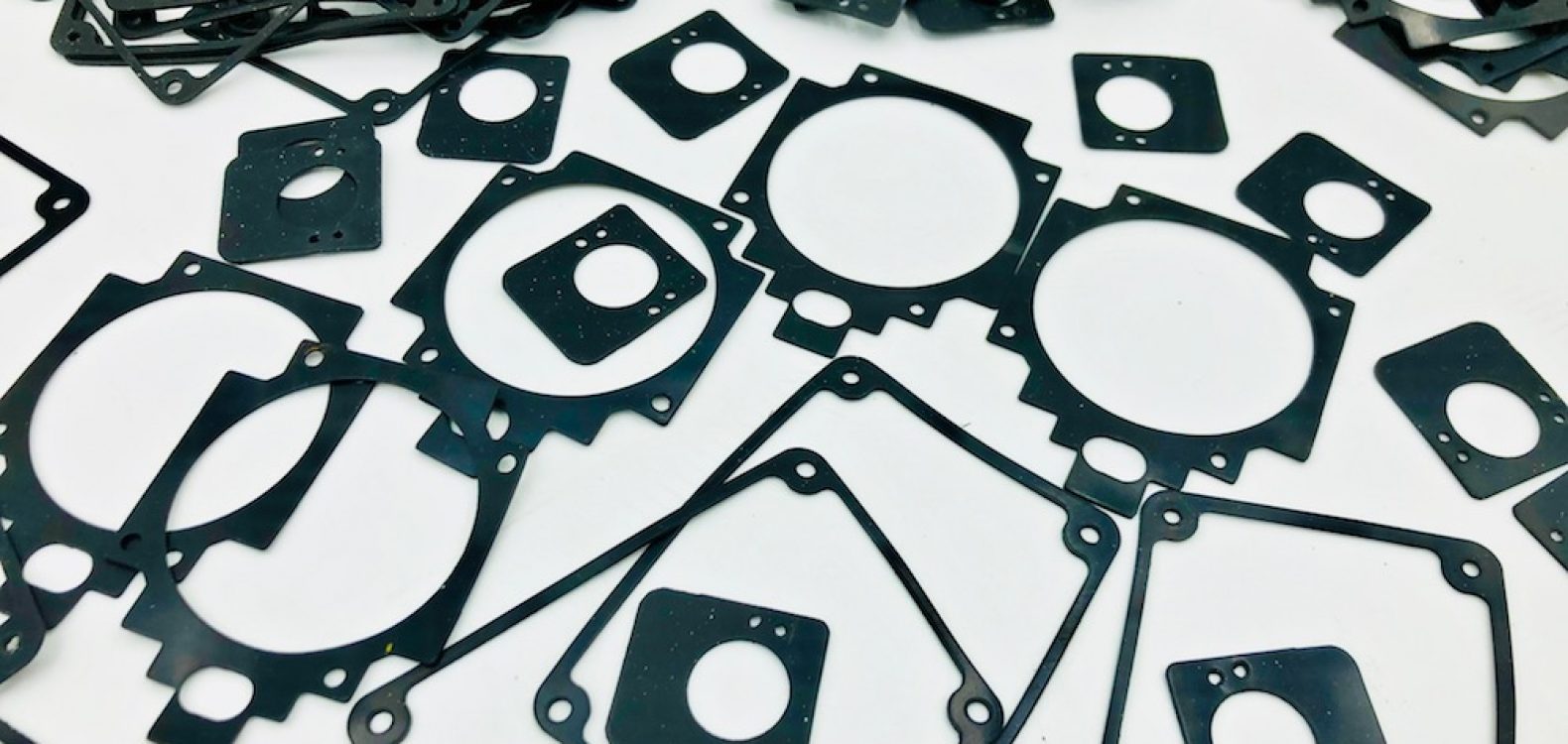

Dilatation seals can be constructed from a wide range of materials, depending on the specific application and environmental conditions. Common materials include:

a. Rubber: Natural rubber or synthetic elastomers like neoprene are often used due to their flexibility and resistance to temperature variations.

b. Metal: Stainless steel, aluminum, or other metals can be used for more robust applications, such as in high-temperature environments or heavy industrial settings.

c. Fabric: Fabric-reinforced seals are lightweight and flexible, making them suitable for certain architectural or transportation projects.

d. Concrete: In construction, dilatation joints can be constructed using specialized precast concrete elements.

4. Applications:

Dilatation seals are applied in various sectors and industries:

a. Construction: In buildings and infrastructure, they are used in bridges, highways, buildings, parking garages, and airports to prevent structural damage from temperature fluctuations and ground movement.

b. Transportation: Expansion joints in roads, bridges, and railways absorb the stresses generated by vehicular traffic and temperature changes.

c. Industrial: In industrial facilities, dilatation seals are employed in piping systems, storage tanks, and manufacturing equipment to manage thermal expansion and contraction.

d. Aerospace: In aerospace applications, expansion joints accommodate changes in the shape of fuselage structures due to varying aerodynamic pressures.

e. Marine: On ships, dilatation seals are used to seal openings in the hull to prevent water ingress while allowing for structural movement.

5. Maintenance and Lifespan:

Proper maintenance and inspection are essential to ensure the longevity and effectiveness of dilatation seals. Regular checks for wear, damage, or signs of failure are crucial, and damaged seals should be replaced promptly to maintain structural integrity.

In summary, dilatation seals are vital components in the built environment, transportation, and various industrial applications. They provide a reliable means to manage the expansion and contraction of materials and structures, preventing damage, ensuring safety, and maintaining the integrity of infrastructure and equipment. Choosing the right type and material for a specific application is critical to the success and longevity of dilatation seals.