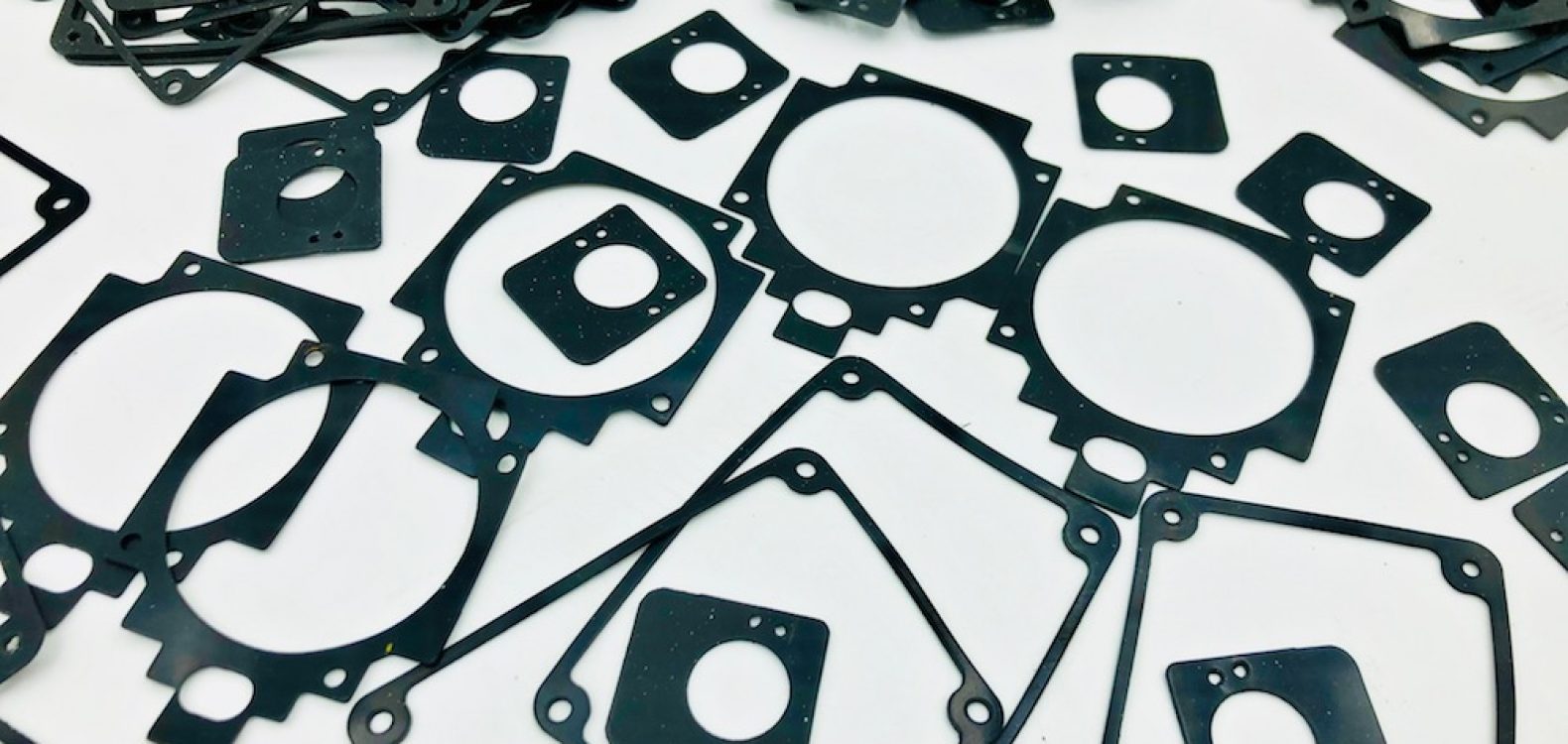

EPDM (Ethylene Propylene Diene Monomer) rubber gaskets are commonly used sealing components known for their excellent resistance to weathering, ozone, ultraviolet (UV) rays, and a wide range of chemicals. EPDM rubber is a synthetic elastomer that exhibits remarkable durability and flexibility, making it suitable for various sealing applications. Here’s more information about EPDM rubber gaskets:

- Material Characteristics:

- Weather Resistance: EPDM rubber is highly resistant to outdoor weather conditions, including sunlight (UV rays), rain, snow, and temperature fluctuations. This makes it ideal for outdoor and exposed applications.

- Chemical Resistance: EPDM rubber provides good resistance to a wide range of chemicals, acids, and bases, which makes it suitable for use in diverse industries.

- Temperature Range: EPDM rubber gaskets can withstand both high and low temperatures, making them functional in extreme environments.

- Flexibility: EPDM rubber is flexible and can conform to irregular shapes and surfaces, providing effective sealing even in challenging conditions.

- Applications:

- Automotive: EPDM gaskets are commonly used in the automotive industry for sealing various components, including doors, windows, hoods, and engine compartments.

- Construction: EPDM rubber gaskets are used in the construction industry for sealing windows, doors, roofing, and HVAC systems.

- Electrical: In the electrical industry, EPDM gaskets can be found in electrical enclosures and cabinets to provide environmental seals.

- Industrial: EPDM gaskets are used in various industrial applications, including sealing flanges, pipes, tanks, and equipment.

- Marine: Due to its resistance to saltwater and UV radiation, EPDM rubber is used in marine applications for hatch seals, porthole gaskets, and more.

- Agriculture: EPDM gaskets are used in agricultural equipment and machinery for sealing purposes.

- Types of EPDM Gaskets:

- O-Rings: EPDM O-rings are used for dynamic sealing applications where compression and deformation are required to create a seal.

- Flat Gaskets: Flat EPDM rubber gaskets are used in static sealing applications where two surfaces come together with little to no movement.

- Gasket Sheets: EPDM gasket sheets come in various thicknesses and can be custom-cut to fit specific applications.

- Installation and Maintenance:

- Proper installation and torque of fasteners are essential for achieving an effective seal with EPDM gaskets.

- Periodic inspection and maintenance are necessary to ensure that EPDM gaskets remain in good condition. Over time, exposure to UV radiation and environmental factors can cause deterioration, so replacement may be required.

- Compliance and Standards:

- EPDM rubber gaskets may need to meet specific industry or regulatory standards, such as ASTM, FDA (for food-grade applications), or others, depending on the application.

EPDM rubber gaskets are versatile, durable, and widely used for their sealing properties in a broad range of industries and applications. Proper selection, installation, and maintenance are essential to ensure their long-term effectiveness and reliability.