Ethylene Propylene Diene Monomer (EPDM) seals and gaskets are essential components used across a wide range of industries for sealing applications. These rubber-based materials offer a remarkable combination of properties that make them well-suited for various sealing and gasketing needs.

Chemical Composition:

EPDM is a synthetic rubber compound composed primarily of ethylene, propylene, and a diene monomer, typically 5-ethylidene-2-norbornene (ENB). The incorporation of the diene monomer into the polymer chain enables cross-linking during vulcanization, enhancing the material’s durability and resilience.

Key Properties:

- Excellent Weather Resistance: EPDM seals gaskets are renowned for their outstanding resistance to outdoor environmental factors. They can endure prolonged exposure to sunlight, ozone, and extreme temperatures, without suffering from significant degradation. This property makes EPDM an ideal choice for outdoor applications, including automotive weatherstripping and roofing systems.

- Water and Steam Resistance: EPDM is highly impermeable to water and steam, making it an excellent choice for sealing applications where moisture or vapor resistance is crucial. This property is particularly valuable in the construction of water-tight seals in plumbing, HVAC systems, and industrial equipment.

- Chemical Resistance: EPDM exhibits good resistance to a wide range of chemicals, acids, and alkalis, making it suitable for applications where exposure to various fluids is expected.

- Flexibility and Elasticity: EPDM possesses exceptional flexibility and elasticity, allowing it to maintain its sealing performance even when subjected to dynamic movements, vibrations, or fluctuations in temperature.

- Low Temperature Flexibility: EPDM remains flexible and retains its sealing properties at low temperatures, making it an ideal choice for applications in cold climates.

- Electrical Insulation: EPDM is an excellent electrical insulator, which is vital in electrical enclosure gaskets and other applications requiring electrical isolation.

- Longevity: EPDM seals and gaskets have a proven track record of long service life, reducing the need for frequent replacements and maintenance.

Applications:

EPDM seals and gaskets find application in a diverse range of industries, including:

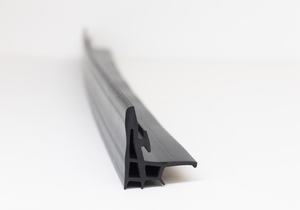

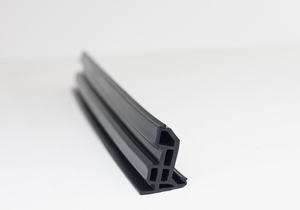

- Automotive: EPDM gaskets and seals are used in vehicle door seals, window seals, engine gaskets, and various under-the-hood components.

- Construction: EPDM is commonly used for roofing systems, curtain wall seals, and glazing gaskets due to its weather resistance and durability.

- HVAC and Plumbing: EPDM gaskets are used in pipe seals, valve seals, and various components in heating, ventilation, air conditioning, and plumbing systems.

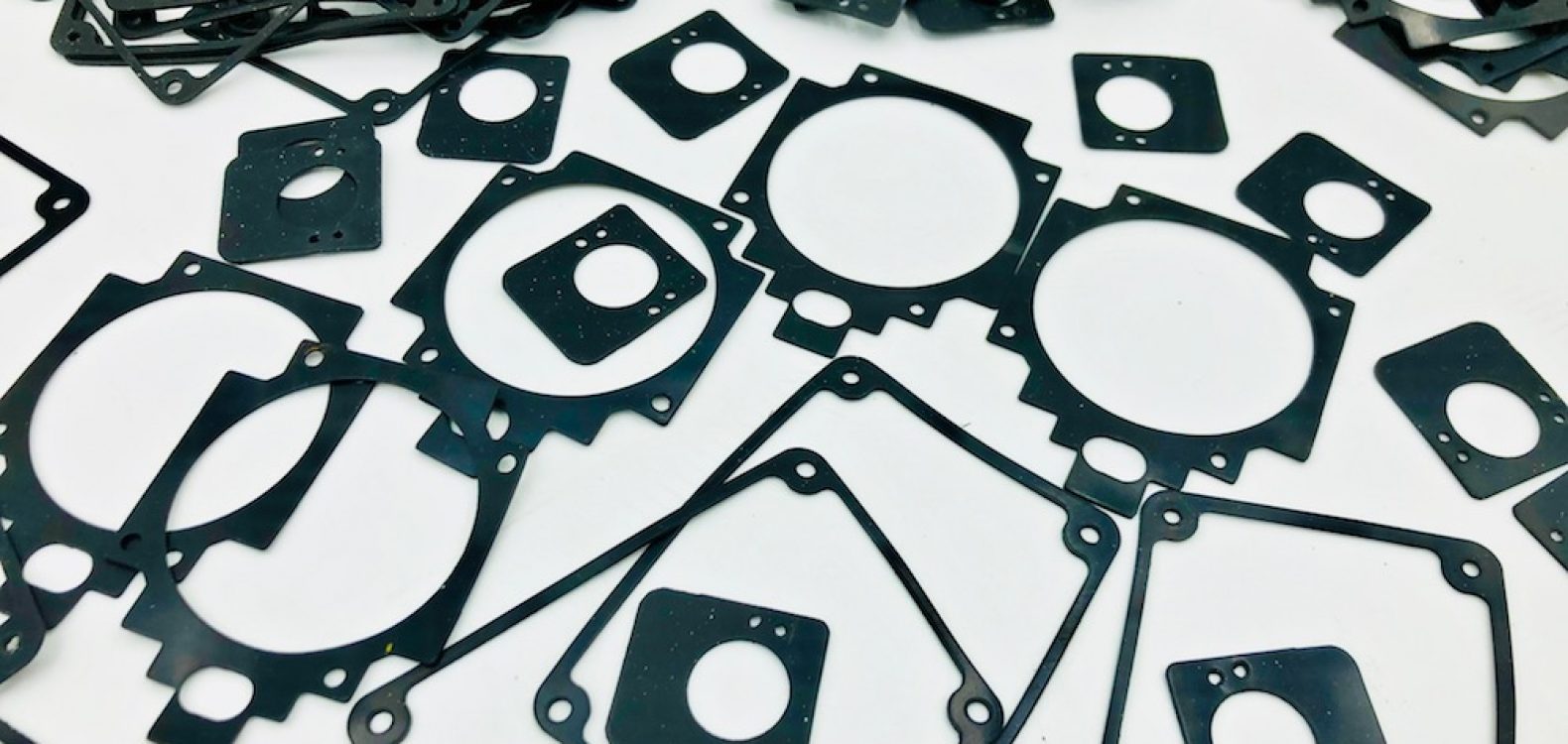

- Industrial Equipment: EPDM seals and gaskets are used in industrial machinery and equipment where chemical resistance and sealing performance are critical.

- Electrical Enclosures: EPDM gaskets are used to seal electrical enclosures, ensuring protection against moisture and contaminants.

- Aerospace: EPDM gaskets find applications in the aerospace industry due to their resistance to aviation fuels and extreme environmental conditions.

- Food and Beverage: EPDM is used in food and beverage processing equipment due to its non-toxic, FDA-compliant nature.

- Marine: EPDM seals and gaskets are used in marine applications for their resistance to saltwater and UV radiation.

In summary, EPDM seals and gaskets are versatile and reliable sealing solutions that offer a unique blend of properties, making them indispensable in a wide range of industries and applications where sealing performance, durability, and longevity are essential. Whether it’s protecting against the elements in construction, maintaining automotive integrity, or sealing critical components in industrial machinery, EPDM continues to be a trusted material choice.