EPDM (Ethylene Propylene Diene Monomer) rubber seals are widely used in various industries and applications for their excellent sealing properties and resistance to environmental factors. EPDM rubber is known for its flexibility, durability, and ability to maintain its sealing performance over a wide range of temperatures and conditions. Here’s more information about EPDM rubber seals:

Material Characteristics:

- Weather Resistance: EPDM rubber seals are highly resistant to weathering, including exposure to sunlight (UV radiation), rain, snow, and temperature variations. This makes them suitable for outdoor and exposed applications.

- Chemical Resistance: EPDM rubber offers good resistance to many chemicals, acids, bases, and oxidants, making it versatile for use in various industries.

- Temperature Range: EPDM rubber can withstand a broad temperature range, from extremely cold to moderately high temperatures, without losing its sealing properties.

- Flexibility: EPDM rubber is flexible and elastic, allowing it to conform to irregular surfaces and maintain a tight seal even in dynamic or moving applications.

Applications:

EPDM rubber seals find widespread use in a range of applications, including:

- Automotive: EPDM seals are commonly used for door and window seals, weatherstripping, gaskets, and hoses in vehicles.

- Construction: In construction, EPDM rubber seals are used for sealing doors, windows, roofing systems, and HVAC ducts to provide weatherproofing and insulation.

- Industrial: EPDM seals are employed in industrial equipment, machinery, and piping systems to prevent leaks and provide environmental protection.

- Electrical: In the electrical industry, EPDM seals are used in enclosures and cable management systems to protect against moisture and dust.

- Marine: Due to their resistance to saltwater and UV radiation, EPDM seals are used in marine applications, including sealing hatches, portholes, and boat components.

- Agriculture: EPDM seals are used in agricultural machinery and equipment to provide sealing and insulation.

- Food and Beverage: In the food industry, EPDM seals are used in processing equipment, storage tanks, and containers where FDA-compliant materials are required.

Types of EPDM Seals:

- O-Rings: EPDM O-rings are commonly used for dynamic sealing applications where they are compressed to create a seal, such as in hydraulic systems.

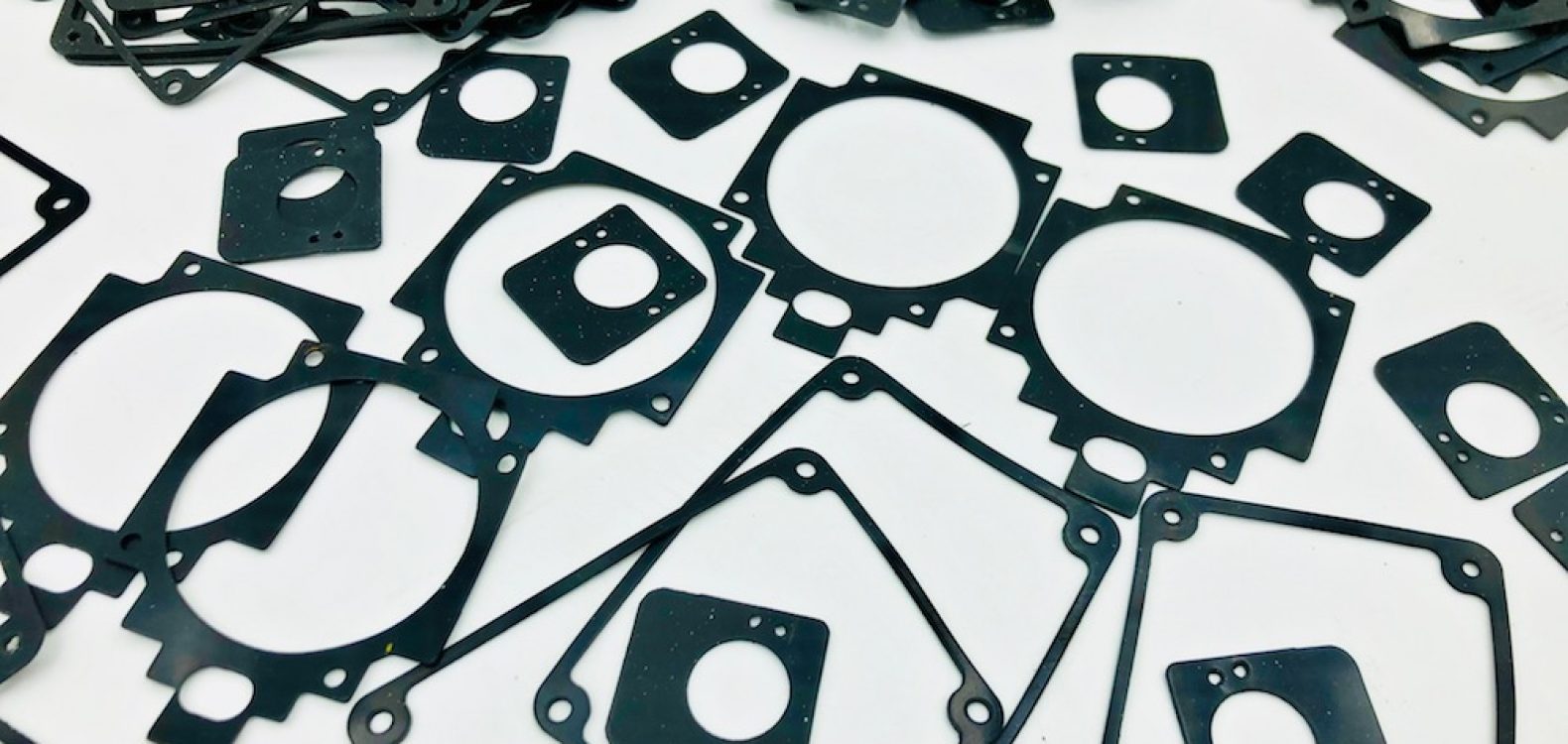

- Flat Gaskets: Flat EPDM rubber gaskets are used in static sealing applications, where two surfaces come together with little or no movement.

- Tubing and Hoses: EPDM rubber is used in the manufacture of hoses and tubing for various fluid transfer applications.

Installation and Maintenance:

- Proper installation techniques, including selecting the appropriate seal type and ensuring clean and dry surfaces, are essential for achieving effective sealing with EPDM seals.

- Regular inspection and maintenance are necessary to monitor the condition of EPDM seals. Over time, exposure to environmental factors can lead to wear and deterioration, necessitating replacement.

Compliance and Standards:

- EPDM rubber seals may need to meet specific industry or regulatory standards, such as ASTM or FDA (for food-grade applications), depending on the application and industry requirements.

In summary, EPDM rubber seals are highly versatile and widely used for their sealing capabilities and resistance to environmental factors. They are essential components in many industries and applications where reliable sealing is critical. Proper selection, installation, and maintenance are key to ensuring their long-term performance.